Evolving Your Project: Unveiling the Intricate Fabrication Process at Our Factory

- kkbuildingglobal

- Sep 19, 2024

- 1 min read

Updated: Sep 23, 2024

Have you ever wondered about the process that happens behind the scenes when you entrust your project to our factory? Today, we invite you on a journey through the fascinating world of fabrication as we unveil the intricate process that brings your ideas to real project at jobsite.

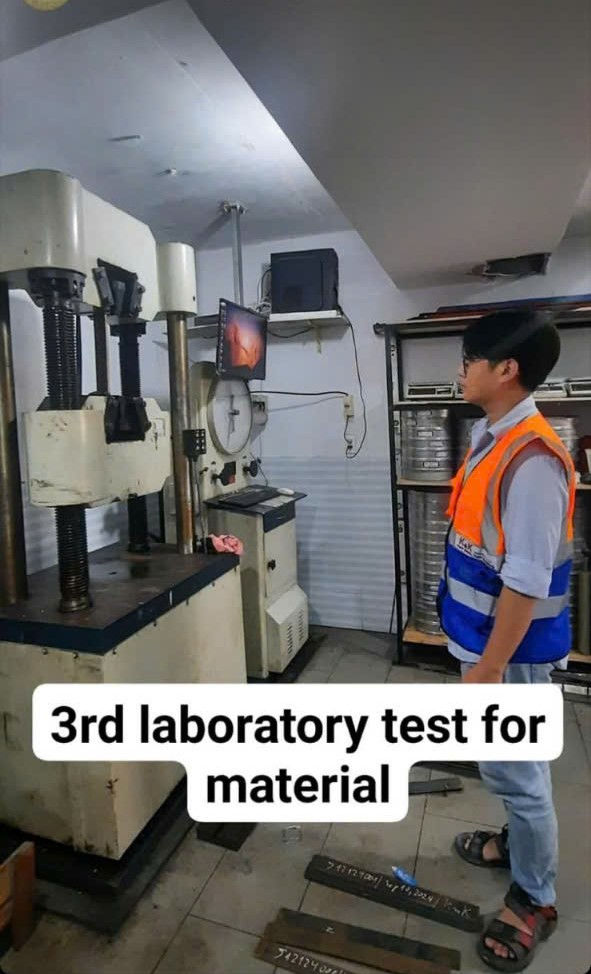

Step 1: Testing material at 3rd party laboratory:

Step 2: Cutting material by laser machine:

Step 3: Welding material by automatic machine:

Step 4: All connection plate, base plate and stiffener are welded by skilled workers:

Step 5: All dimensions of product shall be checked by QC engineer in house:

Step 6: QC engineer shall check quality of all welding line by MT/UT test by 3rd party laboratory:

Step 7: Quality of painting shall be checked by QC engineer before loading:

Step 7-1: Quality of Hot Dip Galvanized shall be checked by QC engineer before loading:

Step 8: Client come to our factory to check product before shipment:

Step 9: Loading product to container 40 foot and start to deliver to all over the world:

Let's evolve your project together – one intricate detail at a time.

Thank you for engaging with our blog post on the fabrication process in K&K factory. Stay tuned for more insights into our world of creativity and craftsmanship.

Comments